Discover the Magic of Freeze Drying: A Beginner's Guide!

Food spoilage, an inevitable natural process, can lead to the growth of harmful microorganisms like bacteria and mold in our food, making it unsafe to consume.

Drying is a preservation method that has been used for centuries to extend the shelf life of food. By removing water from food, microorganisms are unable to grow, and the food can be stored for long periods of time without spoiling.

In today's modern era, various drying methods are employed, such as air drying, oven drying, and freeze drying. Among these, freeze drying has been gaining significant popularity due to its gentle approach to preserving food.

Unlike other drying methods, freeze drying ensures that the flavor, texture, and nutrients of the food remain intact, making it a preferred choice for preserving the quality of the food.

Freeze drying involves the freezing of food at an extremely low temperature, followed by the removal of water in a vacuum. During this process, the water undergoes sublimation, transitioning directly from a solid to a gaseous state.

The removal of approximately 98% of the water content through freeze drying bestows incredible stability and longevity upon the food.

The concept of freeze drying was first developed during the early 1900s, although it wasn't until the 1950s that it became commercially available.

Initially utilized by the military for preserving food for extended periods, this ingenious preservation method has gradually found its way into homes worldwide.

Since their debut in 2010s, home freeze dryers have gained popularity and interest because of the their convenience and efficiency. During home freeze dryers introduction to the market their price was about 5,000$. However, with advancement in technology and increase in demand, freeze dryer cost decrease below 2,500$.

What is freeze drying?

Freeze drying, also known as lyophilization, is a food preservation technique that exerts minimal impact on the shape, color, nutritive value, and taste of the products. It has earned its reputation as a high-quality drying method owing to several compelling reasons:

-

Minimized Chemical, Microbiological, and Enzymatic Reactions: Prior to freeze drying, the food is frozen, effectively reducing chemical, microbiological, and enzymatic reactions. This step ensures that the food's original attributes are retained, and the final product remains fresh and wholesome.

-

Gentle Drying Temperature: Freeze drying employs a significantly lower drying temperature compared to conventional drying technologies. As a result, the heat-sensitive nutrients and aromatic compounds in the food are better preserved, maintaining their nutritional value and delightful aroma.

-

Oxygen-Free Drying Environment: The absence of oxygen in the drying medium plays a pivotal role in preventing oxidation reactions. Oxidation is a leading factor responsible for undesirable flavor and color changes in dried products. By mitigating this process, freeze drying upholds the food's natural appeal.

-

Enhanced Shelf Life: The final products produced through freeze drying contain substantially less water content in comparison to those obtained from other drying methods. This reduction in water content grants the preserved food a significantly extended shelf life, minimizing the risk of spoilage.

-

Minimal Shrinkage, Maximum Rehydration: Unlike alternative drying methods, freeze drying causes much less shrinkage in the dried product. Moreover, the magic of freeze drying doesn't end there. The unique sponge-like microstructure formed during the freeze drying process enhances rehydration.

Because of freeze drying provides high quality it is used in preservation of various foods such as fruits, vegetables, meats, dairy products, herbs, and edible flowers. Moreover, it is also used in drying of biological elements such as probiotics, enzymes and algae in food industry.

How Does Freeze Dryer Work?

Water is a significant component of foods, accounting for approximately 80% to 95% of their composition. This water can be categorized into two types: "free" water and "bound" water. Bound water requires higher energy to remove from foods.

In the freeze drying process, the goal is to eliminate all free water and a portion of the bound water. During the freeze drying process, the free water must remain frozen throughout. In fact, this is the primary difference between freeze and vacuum drying and the most challenging step.

Freeze drying operates through a well-coordinated three-phase process, each playing a vital role in preserving the material's integrity and extending its shelf life.

Phase 1: Freezing Phase

For effective drying of a material in freeze drying, transforming water into ice crystal is extremely important. The freezing of the material can occur in a conventional freezer, a chilled bath (shell freezer), or within the freeze dryer machine itself on a specially designed shelf.

The primary goal in freezing is to cool the water in the material below its triple point, ensuring that sublimation, rather than melting, takes place. This crucial step preserves the material's physical form, locking in its original structure and attributes.

Phase 2: Primary Drying (Sublimation)

The second phase, known as primary drying or sublimation, involves reducing the pressure and giving required energy to the material for sublimation. By doing so, the frozen water in the material directly changes into a vapor (sublimates).

The freeze dryer's vacuum plays a critical role in speeding up the sublimation process, while the cold condenser provides a surface for the water vapor to solidify and adhere to. Additionally, the condenser safeguards the vacuum pump from the water vapor.

During this phase, about 95% of the water ("free" water) content is effectively removed from the material, setting the foundation for its stable preservation. However, this process demands care and precision since applying excessive heat can potentially alter the material's structure.

Phase 3: Secondary Drying (Desorption)

The final phase, termed secondary drying or desorption, targets the removal of remaining water molecules. To accomplish this, the temperature is raised higher than in the primary drying phase, effectively breaking the bonds between the material and the remaining water (some of "bound" water) molecules.

Throughout this phase, freeze dried materials retain their unique porous structure, which is a key characteristic of freeze dried foods. Once the freeze dryer completes its meticulous process, the vacuum can be safely broken.

By diligently following these three fundamental phases, freeze drying achieves exceptional results, yielding materials with a residual moisture content typically ranging from 1% to 5%.

This ensures extended shelf life and unrivaled preservation, making freeze drying a preferred method for maintaining the quality and integrity of various products.

The Science Behind Freeze Drying

At the heart of freeze drying lies the fundamental principle of sublimation – a captivating phenomenon where a substance shifts directly from its solid state to a gaseous state. Similar to evaporation, sublimation occurs when individual molecules acquire enough energy to break free from their surrounding molecules.

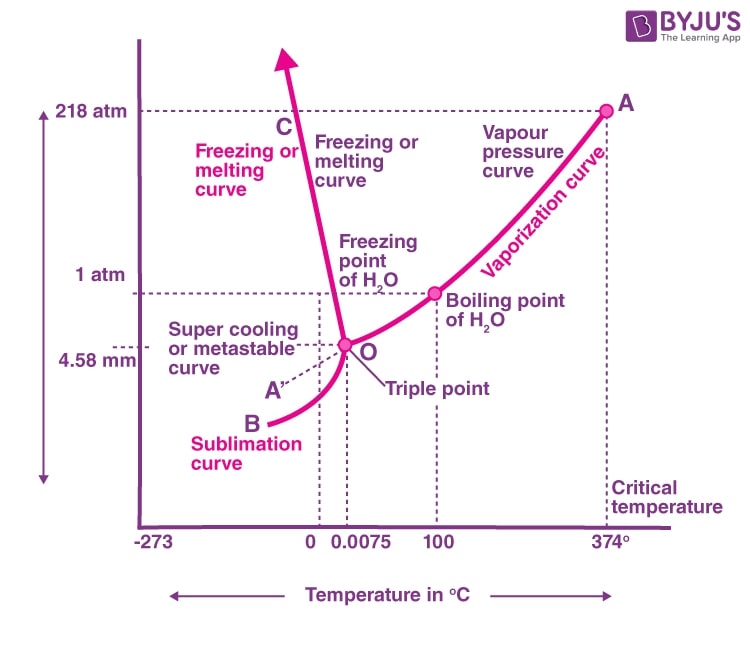

Two significant factors, heat and atmospheric pressure, decisively determine the phase a substance adopts. For a substance to exist in a particular phase, both temperature and pressure must fall within specific ranges. The chart below illustrates the required pressure and temperature values for water in different phases.

The chart shows, water can exist in its liquid form if the temperature lies between the freezing point (32 degrees Fahrenheit or 0 degrees Celsius) and boiling point (212 F or 100 C) at sea level (where pressure equals 1 atm).

However, should the temperature rise above 32 F while the atmospheric pressure remains below 0.06 atm (610 Pa), the water is warm enough to thaw, but the insufficient pressure prevents a liquid from forming, leading to its transformation into a gas. This principle lies at the core of freeze drying machines.

Typically, a freeze dryer machine comprising a leakproof drying chamber with multiple shelves attached to heating units, a freezing coil connected to a refrigerator compressor, and a vacuum pump.

In a freeze dryer machine, during drying the vacuum pump activates, reducing the atmospheric pressure below 0.06 atm (610 Pa). Meanwhile, the heating units apply gentle heat to the shelves, causing the frozen ice to undergo sublimation.

The heat of sublimation is 2885 kJ/kg. If too little heat is supplied, the process will be slow, which will increase the process costs. If the supplied heat flux is too high, it will cause an accumulation of heat in the material and an increase in its temperature, consequently leading to the possibility of the appearance of liquid water. Hence, it is extremely important to maintain a balance between the amount of heat supplied and used.

The water vapor then flows out of the freeze drying chamber and condenses onto the freezing coil in solid ice form.

This intricate process unfolds over many hours, even days, to ensure a gradual and precise drying of the material. Rushing the process could significantly alter the composition and structure of the material, leading to negative results. Hence, the time-consuming nature of freeze drying guarantees optimal preservation while retaining the material's quality and integrity.

Advantages of Freeze Drying

Freeze drying offers a host of exceptional advantages, making it a preferred choice for preserving a wide array of products.

Preservation of Nutritional Value

Traditional preservation methods like dehydration and canning involve heating the food to temperatures that can degrade its nutritional content by breaking down vital vitamins and minerals, such as vitamins A and C, thiamine, riboflavin, and niacin. Moreover, these methods can adversely affect taste and texture.

On the other hand, freeze drying has ability to safeguard the nutritional value of foods. Freeze drying ensures that sensitive nutrients like vitamins and enzymes remain intact, preserving the original nutritional content of the material.

Extended Shelf Life

Freeze dried foods have earned a reputation as the champions of long-term storage, boasting an impressive shelf life that surpasses many other preservation methods.

Dehydrated products like dried fruits, vegetables, powders, and soy protein typically maintain their quality for several years. However, freeze dried foods, including fruits, vegetables, meats, and herbs, excel with an average shelf life of approximately 25-30 years or even more.

Retention of Flavor and Aroma

Unlike some preservation methods that alter the taste and aroma of products, freeze drying stands as an exception, maintaining the authentic flavors and enticing aromas of the original material. This preservation of natural taste makes freeze dried foods and products more appealing to discerning consumers.

Lightweight and Easy Transportation

Freeze drying process, extracts approximately 98% of a food's water content, leading to a tremendous reduction in weight. Freeze dried foods can weigh as much as 90% less than their original form.

Therefore, freeze dried foods are more cost-effective and convenient to transport, particularly for long distances or space missions.

Emergency Preparedness

Freeze dried meals and food items have found a prominent place in emergency preparedness kits. With their extended shelf life, they serve as reliable sources of nourishment during unforeseen events like natural disasters, offering sustenance and comfort when needed most.

Step-by-Step Guide to Freeze Drying

Here's a step-by-step guide to the freeze drying process:

- Step 1: Preparing the Material

- Step 2: Freezing

- Step 3: Sealing the Drying Chamber

- Step 4: Cooling the Coils

- Step 5: Creating a Vacuum

- Step 6: Desorption

- Step 7: Completion and Packaging

- Step 8: Enjoying the Freeze Dried Foods

For more information read our Step-by-Step Guide to Freeze Drying article

Freeze Dryer vs Dehydrator

You may wonder that is a freeze dryer and a dehydrator the same thing The short answer is no.

While both freeze dryers and dehydrators are food preservation methods, they differ significantly in their processes, results, and characteristics. Let's take a look at the key differences between these two food preservation methods through a comparison table:

| Parameter | Freeze dryer | Dehydrator |

|---|---|---|

| Principle | Sublimation and Desorption | Evaporation |

| Temperature | Typically operates at -40°F to -60°F. | Typically operates at 120°F to 160°F. |

| Time | Typically 24-48 hours. | Typically 6-12 hours. |

| Moisture content | 1-3% | 5-20% |

| Texture | Crispy and chewy | Soft and leathery |

| Flavor | Preserves flavor and taste | Lose some flavor and taste |

| Nutrient lose | Minimal | High |

| Cost | More expensive than dehydrators. | Less expensive than freeze dryers. |

| Color | Brighter | More muted |

| Shrinkage | No or minimal | High |

| Preservation | Long Shelf Life (Up to 25 years) | Shorter Shelf Life (Several Months to a Few Years) |

| Quality | High | Low |

| Energy Consumption | High | Low |

In summary, freeze dryers and dehydrators present distinct differences in their operating principles, temperature ranges, and final product preservation quality.

Your particular requirements and tastes will determine whether you should use freeze dryer or dehydrator. A freeze dryer is the best choice if you seek high-quality, long-lasting preservation with little nutrient loss. A dehydrator is a good option, too, if you're looking for a more affordable way to preserve items for a shorter period of time with softer textures.

Discover more difference between dehydrator and freeze dryer

Tips for Successful Freeze Drying

Freeze drying is a meticulous process that requires careful attention to detail to achieve the best results. Follow these essential tips to ensure successful freeze drying and preserve the quality of your foods effectively:

-

Preparation: Achieving a high-quality final food product in freeze drying relies on starting with high-quality raw materials. Given the costliness of the freeze drying process, it is imperative to select premium raw materials. Thoroughly clean, wash, and meticulously separate any unwanted materials to ensure uniformity and a superior end result in the freeze dried foods.

-

Proper Cutting and Slicing: The efficiency of the freeze drying process hinges on uniform and appropriately sized cuts or slices of the raw material. Opt for smaller pieces, as they freeze and dry more efficiently, leading to better overall results. In contrast, heterogeneous cutting and slicing can result in varying quality and a shorter shelf life for the final freeze dried product.

-

Blanching: For certain vegetables, blanching is an essential step in the preparation process. Blanching aids in preserving the natural color, texture, and flavor of the vegetables while reducing enzyme activity. Additionally, blanching decreases the volume of certain materials, increasing their capacity to be effectively freeze dried.

-

Quick Freezing: Quick freeze the raw material at lower temperatures and air circulated freezing system. This approach results in the formation of smaller ice crystals, contributing to better overall quality in the freeze dried foods.

-

Check the Seals: Before initiating the freeze drying process, carefully inspect all sealings to ensure their integrity. Proper sealings are crucial as they directly impact the vacuum level in the freeze drying chamber.

-

Adjusting Vacuum: Maintain precise control over the vacuum pressure, ensuring it remains below 0.06 atm. This is the crritical vacuum level for the sublimation .

-

Balancing Temperature: Throughout the freeze drying process, set appropriate temperatures to prevent overheating of the material and shorten the drying time. Proper temperature control not only preserves flavors and nutrients but also minimizes drying costs.

-

Defrosting: Regularly defrost the ice on the freezing coil. After each freeze drying run, ensure to defrost the condenser and drain the water.

-

Packaging Carefully: Freeze dried materials possess low moisture content and a sponge-like microstructure, making them highly hygroscopic. Therefore, freeze dried material must be packaged in air-thight packaging materials such as mylar bags or jars.

-

Storage Conditions: Store freeze dried foods in a cool, dry place away from light and heat. Proper storage extends their shelf life and maintains quality.

-

Regular Maintenance: Perform routine maintenance on your freeze dryer to ensure optimal performance and extend its lifespan. Regularly check the quality of the oil and oil filter of the vacuum pump, replacing them when necessary.

How To Store Freeze Dried Food

Freeze dried food can indeed last up to 25 years with proper storage techniques. Ensuring your freeze dried food remains fresh and ready when needed requires attention to detail. Here are some essential tips for storing freeze dried food effectively:

Check for Dryness: After removing the food from the freeze dryer, break a large piece in half and examine the center of the product for any ice particles or coldness. The food should be completely dry throughout. If you find any moisture, return it to the freeze dryer for a short dry cycle. Otherwise, the shelf-life will be much shorter.

Airtight Containers: Place the freeze dried food in airtight containers to prevent moisture reabsorption from the air, which can lead to spoilage over time. Some containers can be used:

-

Mylar Bags: For a 25-year shelf life, Mylar bags are a one of the convenient and cost-effective options. Using an oxygen absorber to the bag to eliminate any remaining oxygen will prevent any oxidation.

-

Vacuum Bags: For most foods, except meats and high-protein items, vacuum-sealed plastic bags work well for short-term storage.

-

Resealable Jars: For short-term storage, resealable jars or containers are suitable. However, when storing meats or long-term food items, oxygen absorbers must be used.

-

Airtight Jars: Simple airtight jars are ideal for storing snacks like fruits and vegetablesfor a few months in the pantry. For these items, you may not necessarily need an oxygen absorber, but ensure the jar is tightly sealed after use.

Remove Air and Moisture: It is crucial to eliminate air and moisture from the packing of freeze dried meals in order to guarantee their durability and quality. Oxygen (21% in air) promotes oxidation reactions that have a negative effect on a product's color, flavor, and taste. Foods that have been freeze dried are particularly susceptible to oxygen deterioration because of their microstructure. Therefore, it is essential to remove oxygen from the package.

It is extremely advised to use the right oxygen absorbers to accomplish this. Oxygen absorbers effectively remove any remaining oxygen from the packaging, preserving the freeze dried food's freshness and nutritional quality. Air cannot enter the container and affect the contents by sealing it tightly after placing a suitable oxygen absorber inside.

Oxygen absorbers come in a variety of sizes to accommodate differing storage requirements. They can be bought in quantity, providing a reasonably priced way to improve preservation.

How Long Does Freeze Dried Food Last

According to a number of variables, including the food's type, storage conditions, and packaging techniques, freeze dried food's shelf life can change. As was already mentioned, foods that have been freeze dried have a special microstructure that makes them vulnerable to oxygen, humidity, and minerals.

Food that has been properly prepared and stored can typically last for 25 to 30 years or even longer. However, a few factors might potentially reduce the food's shelf life:

-

Exposure to oxygen: Oxygen can cause the freeze dried food to oxidize and lose its flavor and nutritional value. Therefore it must be packaged airtight containers.

-

Exposure to moisture: Freeze dried food should not be exposed to moisture, as this can cause it to rehydrate and spoil. If a package of freeze dried food becomes wet, it should be discarded.

-

Extreme temperatures: Freeze dried food should be stored in a cool, dark place. Exposure to extreme temperatures, such as heat or cold, can shorten the shelf life of the food.

Food that has been freeze dried can retain its quality and nutritional value for a prolonged period of time if it is kept in airtight containers, such as Mylar bags or vacuum-sealed bags, in a cool, dry, and dark location with a constant temperature. In order to keep air and moisture out of the packaging, oxygen absorbers are used, which further increases the shelf life of the food.

To make sure the food stays in top condition for the duration of its shelf life, adhere to recommended storage procedures and routinely check the freeze dried food for indications of moisture or packaging damage. By following these recommendations, people can take advantage of the advantages of freeze dried food for a longer period of time, making it an important component of long-term food storage plans.

Does Freeze Dried Food Lose Nutrients

Freeze dried food stands out for its remarkable ability to retain a significant portion of its original nutrients. Unlike conventional drying and preservation methods that involve exposure to high temperatures, freeze drying operates under low temperatures, preserving the nutritional content of the food.

The vacuum environment used in freeze drying ensures the absence of oxygen, minimizing oxidation reactions. As a result, heat-sensitive nutrients like vitamins, minerals, and other essential components present in the food are effectively preserved.

An important advantage of freeze dried food is its resistance to thermal degradation. Heat-sensitive nutrients, such as vitamins and enzymes, remain largely intact throughout the freeze drying process. This sets freeze drying apart from methods like dehydration or canning, which can lead to substantial nutrient loss.

The changes in nutrient content during freeze drying are summarized in the table below:

| Aspect | Changes during freeze drying |

|---|---|

| Calorie | Total calorie remains same but, calorie per unit mass increases because of water remaoval |

| Fiber | No change |

| Vitamin A | Well retained |

| Vitamin B | Well retained |

| Vitamin C | May decrease since sensitive to freezing |

| Vitamin E | Well retained |

| Minerals | No change |

| Phenolics | Well retained |

| Other antioxidants | Well retained |

In a study on determination the effect of storage (using foil laminate pouch under vacuum) at 1, 30 and 40ºC on the vitamin B1, B2, B6 and E of fortified military food, mean 24-month retention rates were determined as 94%, 97%, 86%, 77%, respectively (Source).

Frequently Asked Questions (FAQ)

How Much Is a Freeze Dryer?

The cost of a food freeze dryer machine depends on size, pump, features and capacity of the dryer. For home freeze dryers, the price typically is between $2,000 to $5,000. These models are designed for personal use and can handle smaller batches of food or other materials. On the other hand, commercial freeze dryers, which have higher capacities and more advanced features, can be much more expensive.

To find the best option when thinking about buying a freeze dryer, it's critical to evaluate your unique requirements, intended usage, and budget. A wise strategy is to compare various brands and models to make sure you get the best value for your money.

Need suggestions check out "The Best Freeze Dryers of 2023"

How Does a Freeze Dryer Work?

Freeze drying, also known as lyophilization, is a specialized food preservation technique that involves removing moisture from the product while preserving its structure and nutritional properties. Here's a step-by-step explanation of how a freeze dryer works:

-

Freezing: The first step is to freeze the material to be preserved. The temperature of the material is lowered to below freezing, typically around -40°F to -60°F (-40°C to -50°C). This can be done in a separate freezer or directly in the freeze dryer itself. Freezing the material causes the water content within it to turn into ice crystals.

-

Primary Drying (Sublimation): Once the material is frozen, the freeze dryer creates a vacuum in the drying chamber. The process of sublimation takes place, where the ice crystals in the material transform directly into water vapor without passing through the liquid phase. This sublimation process removes about 95% of the water from the material, leaving it in a dry, dehydrated state.

-

Secondary Drying (Desorption): Although most of the water is removed during primary drying, a small amount of bound water may still remain in the material. To eliminate this bound water, the temperature is slightly increased during the secondary drying phase. This encourages the removal of any remaining water molecules, ensuring the material reaches its desired moisture level, typically between 1% to 5%.

-

Packaging: After completing the freeze drying process, the dehydrated material is carefully removed from the freeze dryer. It is then promptly packaged in a manner that prevents reabsorption of moisture. Common packaging methods include using airtight containers like Mylar bags, vacuum-sealed bags, or jars equipped with oxygen absorbers. These packaging choices further safeguard the freeze dried product from exposure to environmental factors that could compromise its quality and longevity.

Is a Freeze Dryer and a Dehydrator the Same Thing?

No, a freeze dryer and a dehydrator are not the same thing. A freeze dryer uses sublimation at low temperatures to remove water from the food. On the other hand, a dehydrator uses evaporation at higher temperatures to remove water from the food.

Therefore, freeze dryers effectively preserve shape, volume, color, flavor and nutritive components in final product. On the other hand, a significant negative change occurs in these properties when dehydrators are used. In addittion to high quality, freeze dried foods have longer shelf life in comparison to dehydrated foods.

Dehydrators are generally more affordable than freeze dryers and consume less energy. They also complete the drying process in shorter durations compared to freeze dryers.

Overall, if you are seeking high-quality, long-lasting preservation with minimal nutrient loss, a freeze dryer is the best choice. However, if you are looking for a more budget-friendly option to preserve items for a shorter period of time with softer textures, a dehydrator can be a suitable option.

How to Build a Freeze Dryer

Building freeze dryer is a complicated project. But with technical knowledge and skill, it’s far from impossible. To build a DIY freeze dryer, vacuum pump, air-thight container, cold-trap, heat source (optional) and tubings are needed. Here are the general steps involved in building a homemade freeze dryer:

- Building drying chamber: An airtight and insulated chamber using food-safe materials must be constructed. The chamber should be able to withstand low temperature and high vacuum.

- Cold-trap: A cold trap is a crucial component in the freeze drying process to prevent water vapor from reaching and potentially damaging the vacuum pump.

- Vacuum Pump: Vacuum level is critical in freeze drying. Therefore choose a suitable vacuun pump. Connect the vacuum pump to the chamber using proper tubing.

- Heat source: Optionally integrate the heat source in the drying chamber.

Need some video guides - Click Here

Where to Buy a Freeze Dryer

Here are some of the most popular brands of home freeze dryers:

These brands offer a variety of freeze dryers to choose from, so you can find one that fits your budget and needs.

Do You Have to Defrost Freeze Dryer Between Batches

Yes you do. Defrosting the freeze dryer is essential to maintain its efficiency and optimal performance between batches. Regular defrosting helps remove built-up ice from the condenser and freezing coils, ensuring proper functionality and uniform drying results for each batch.

The frequency of defrosting may vary depending on the duration and severity of the freeze drying process. Following the manufacturer's instructions on how often and how to defrost the freeze dryer is crucial to prolong its lifespan and prevent potential damage.

By conducting regular defrosting and adhering to proper maintenance practices, the freeze dryer can continue to operate effectively, providing high-quality freeze dried products for an extended period.

For more information click here

Do Freeze Dried Foods Need Refrigeration

No, freeze dried foods do not need refrigeration. Freeze drying removes almost all the water content from the food, making it highly stable and resistant to spoilage.

Therefore, they can be stored at room temperature for an extended period without the need for refrigeration. As long as the freeze dried foods are properly packaged and stored, they can maintain their quality and freshness for a long time.

Do Freeze Dryers Use a Lot of Electricity

The electricity consumption of a freeze dryer is directly related to the drying time, loading amount, size, capacity, and usage frequency. Depending on these conditions, the total electricity consumption for a complete freeze-drying process (including freezing, drying, and final drying) can range between 12-30 kWh in 24-36 hours of operation.

For more information on freeze dryer electricity consumption click here

Conclusions

In conclusion, freeze drying is a highly effective food preservation technique that offers numerous benefits, making it a popular choice for preserving a wide variety of products. By removing water through sublimation and desorption, freeze drying maintains the integrity and quality of the food, retaining its flavor, texture, and nutritional value.

This preservation method excels in providing long shelf life, making it suitable for emergency preparedness and long-term storage needs.

When compared to dehydrators, freeze dryers yield dried products of superior quality, albeit at a higher cost and energy consumption.

To ensure successful freeze drying, attention to detail in material preparation, freezing, vacuum creation, temperature adjustment, and proper packaging is crucial. Regular maintenance of the freeze dryer is also essential for optimal performance.

Proper storage techniques, such as using airtight containers and oxygen absorbers, help maintain the freshness and quality of freeze dried food for up to 25 years or more.

Newsletter

Subscribe to our newsletter for the latest updates, tips, and insights on freeze drying! Stay informed about new recipes, product reviews, and exclusive offers from 'DryAtHome.'

By Singing Up, You Agree ToPrivacy Policy