Freeze Dryer vs Dehydrator

Dr. Tontul

Dr. Tontul- 11 Sep 2023

In the world of food preservation, the age-old question remains: Freeze Dryer or Dehydrator? Although a food dehydrator and a freeze dryer are both used in food preservation, they are based on principles that provide different qualities in the end product

The process of a food dehydrator involves circulating heated air around the food and gradually removing moisture over an extended period of time. This method finds widespread application for fruit, vegetables and meats. Usually within a few hours, most of the water in the food is removed. However, as a high temperature process, it can cause undesirable changes in the physical, chemical and sensory properties of the food.

Freeze-drying, on the other hand, uses sublimation to remove moisture from foods. In this technique, foods are subjected to low pressure conditions after being frozen. This allows water molecules to completely bypass their liquid phase and pass directly from ice solids to gas form. This procedure has minimal impact on the physical, chemical and sensory properties of the food and allows the food to be dried to a lower moisture content. However, the investment and operating costs are considerably higher compared to alternative drying methods.

Therefore, significant disparities exist between dehydration and freeze drying, although both approaches can be used in dry food production. This article can help you gain an in-depth understanding of the differences between the two methods and facilitate the process of determining the appropriate method for your desired dry food production.

Freeze Dryer vs Dehydrator: Principle

The art of food drying revolves around the task of removing moisture, which is home to bacteria and other microorganisms. This process should not only prolong the life of the food, but also preserve its nutritional value. There are numerous methods for drying edible foods, with two particularly attractive options standing out: food dehydrators and freeze dryers.

The most important difference between dehydrators and freeze dryers is the temperature at which these devices operate. Dehydrators operate between 95°F (35°C) and 212°F (100°C) and use heat to remove moisture from food.

In contrast, freeze dryers make use of sublimation. In this method, at the right combination of temperature (usually -40ºF and lower) and pressure, the frozen water in the food passes directly from the solid state to the vapor state. This cold process provides a unique nutritional quality that cannot be achieved with dehydration techniques.

Another important contrast lies in the physical properties that each method imparts to the final product. Dehydrators often provide products with a shriveled or leathery consistency due to the application of high temperatures throughout processing.

In contrast, freeze-dried foods retain their natural shape and texture as faithfully as possible, as they undergo minimal structural changes during sublimation.

Freeze Dryer vs Dehydrator: Physical quality of final product

The physical quality of food is an important factor influencing consumer liking during the purchasing and consumption process.

Important physical properties of dried foods are color, shape, appearance, texture and rehydration. Depending on the conditions applied during the drying process, more or less changes occur in these physical properties.

In many applications, it has been observed that freeze-dried foods are much better in terms of physical properties than their dehydrated alternatives.

Color

The application of much milder temperatures during freeze drying causes minimal changes in the color of the food. Moreover, the process is carried out under vacuum, which significantly reduces oxidation reactions. Thus, there is no loss of the components that give the food its color.

On the other hand, dehydration as a technique involving heat triggers various reactions that affect the color of the product. For example, the Maillard reaction, a reaction between sugars and amino acids that accelerates with temperature, results in browning. At the same time, color pigments such as chlorophyll, anthocyanin and carotenoids in the product oxidize and cause color change.

This color change is clearly visible in the image below.

public\images\posts\freeze-dryer-vs-dehydrator-color.jpg So why is the color of dehydrated industrial dried food better than that of home-produced food? Because, in industrial dehydration applications, some additives can be used to prevent or limit this color change. For this purpose, various agents such as ascorbic acid, citric acid, sulfur dioxide are used.

Shape

The shape of the dried products is one of the main differences between dehydrators and freeze dryers. Freeze drying preserves the original shape of the dried food, giving a more robust and visually appealing result. In contrast, dehydrators often cause shrinkage and deformation due to their high temperatures.

From a consumer perspective, the shape affects how attractive a dried product looks on store shelves or when presented as part of a meal. Freeze-dried products tend to retain their natural shape with minimal distortion or damage during processing, which increases their visual appeal compared to dried alternatives that are shriveled or less aesthetically pleasing.

Texture

Texture plays a crucial role in the holistic sensory encounter of a foodstuff. Smoothness, roughness, firmness and chewiness are just some of the physical characteristics that can be distinguished through the delicate art of touch. The final texture of a product is formed by the interaction of various elements such as the ingredients used, the processing techniques applied and the presence of additives.

An attractive mouthfeel has uncanny powers that can not only enhance the perception of flavor, but also create deep satisfaction with every bite savored. For this reason, the texture of dried products is very important.

An important factor that has an impact on textural properties is moisture content. The moisture level has the power to shape the essence of crispness or softness in gastronomic delicacies.

In general, freeze-dried products have a much lower moisture content than their dehydrated alternatives. Freeze drying therefore allows the production of crispier products. Freeze-dried products have a firmer texture, while dehydrated products are generally softer and leathery.

However, it should be emphasized that there may be different expectations from different products in terms of textural properties. For example, soft and chewy dried apricots are more acceptable for some consumers. Therefore, it is not possible to say that one of these methods is superior to the other in terms of textural properties.

Rehydration

The ability to rehydrate is of great importance in the production of dried foods. It entails the complex task of infusing moisture back into the dried product and thus reviving its original properties and flavor. Good rehydration requires minimal impact on the components present in the food during the drying process, such as polysaccharides, proteins and hydrocolloids, which interact with water.

In the dehydration process, which is a thermally applied process, the starch in the food can reach temperatures close to the gelling temperature. Moreover, denaturation of proteins also occurs. In addition, there is shrinkage of the structure and a significant loss of volume of the cells.

All these events negatively affect the rehydration ability of dehydrated foods. This is why foods dried by this drying method often have poor rehydration ability. This means that it is unlikely to return to its original state when kept in water.

Freeze drying, on the other hand, does not reduce the volume of cells and does not affect the components that interact with water. Therefore, products produced by freeze drying have superior rehydration ability. Indeed, one study found that the rehydration rate of freeze-dried beans was 9-10 times faster than that of dehydrated and vacuum-dried beans. They can recover almost all of the water removed during drying.

However, this does not mean that they have similar textural properties to fresh products. In fact, a rehydrated freeze-dried product is much softer than its fresh alternative.

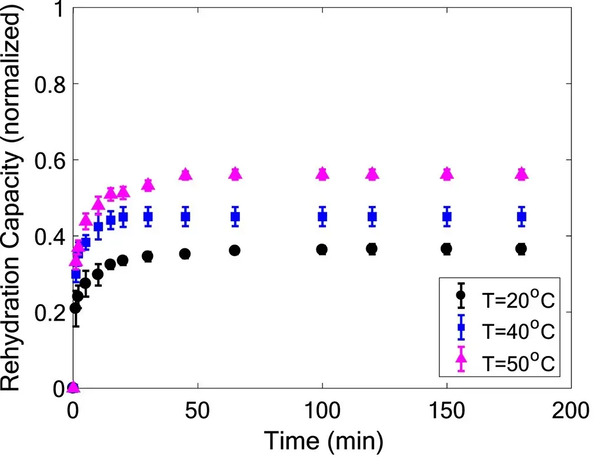

The rate of rehydration and the amount of water absorbed during rehydration depend on the temperature of the water in which the dried material is kept. The higher the temperature, the shorter the rehydration time and the more water the material absorbs.

In a scientific study, it was found that the equilibrium weight of freeze-dried tomatoes was reached in about 50 minutes by keeping them in water at different temperatures. However, increasing the temperature from 20ºC (68ºF) to 50ºC (122ºF) significantly increased the material weight. The results obtained in this study are given below.

Freeze Dryer vs Dehydrator: Chemical quality of final product

Macronutrients

A significant proportion of dehydrated food consists of carbohydrates, proteins, fats and minerals. These components are therefore called macronutrients.

Freeze-drying method has a small effect on the macronutrients in foods. This is mainly due to freezing, especially before the freeze-drying process. If the freezing process is carried out slowly, the components in the food may be localized in the food. This affects the structure of starch and proteins. However, it is possible to prevent these changes with fast freezing processes.

On the other hand, the heat effect applied during dehydration accelerates various reactions in foods. Some of these are oxidation, Maillard reaction and protein denaturation. As a result of these reactions, positive or negative changes may occur in the macronutrients of the food. For example, denaturation of proteins can improve digestibility in some cases.

However, various components such as, furans, furfurals or acrylamide, that can negatively affect human health may form in food as a result of oxidation and Maillard reaction. Therefore, measures need to be taken to prevent the formation of these components.

Vitamins

Some vitamins, such as vitamin C, are very sensitive to various processes, especially heat treatment. Therefore, these vitamins decrease significantly during food processing.

In many scientific studies examining the changes of vitamins during food drying, it has been observed that freeze-drying has less effect on heat-sensitive vitamins than dehydration.

For example, in a study with pepper, freeze drying caused a 43.7% decrease in vitamin C, while dehydration caused a loss between 69% and 86% depending on the temperature. In another study with okra, freeze-drying caused a 9% loss of vitamin C and dehydration caused a 44% loss.

Similar results were obtained for B vitamins (vitamins B1, B2, B3, B5, B6, B7 and B12) in a study with pineapple. However, in the same study, σ-tocopherol, a vitamin E derivative, and vitamin A were higher in the dehydrated sample than in the freeze-dried sample.

Therefore, although some exceptions have been reported, it can be argued that freeze-drying provides a much higher vitamin content than hot air drying.

Antioxidants

Plant foods in particular contain various antioxidant components such as phenolics and pigments. Some of these components are sensitive to high temperature and heating in an oxygenated environment.

Therefore, some of the antioxidant components are degraded or oxidized during dehydration.

However, freeze drying under vacuum and at low temperatures has much less effect on these components.

Indeed, in a study on mint, freeze-dried samples had more than twice the phenolic content and antioxidant activity compared to dehydrated samples. Similar results were obtained in a study with pineapple.

Freeze-dried foods therefore have an important advantage in supporting an antioxidant-rich diet.

Volatile compounds

Volatile compounds are responsible for the aromatic properties of foods. As the name suggests, these components have high volatility. Therefore, even the application of low temperatures causes the loss of these components.

The heat applied during dehydration causes a loss in volatile components, resulting in the final product being perceived as bland. On the other hand, freeze-drying has less impact on aromatic components.

In a study, freeze drying or dehydration at low temperatures of apples has been found to preserve volatile components more effectively.

Freeze Dryer vs Dehydrator: Sensory properties of final product

Sensory properties of foods are a combination of the physical and chemical properties described above. For example, if a food that has very good chemical properties and is expected to be crispy is soft, this causes disappointment in the consumer.

The minimal impact of freeze drying on color and appearance leaves a very positive first impression on consumers. On the other hand, wrinkled and browned dehydrated products lower sensory expectations.

When both products are put into the mouth, the freeze-dried product provides high resistance to the teeth, while the dehydrated product leaves a softer feeling with less resistance. Therefore, freeze-dried product is advantageous for those who like crispy products, and dehydrated product is advantageous for those who love soft products.

Because it undergoes fewer chemical changes and is richer in aromatic components, the flavor of the freeze-dried product is closer to the fresh product. On the other hand, the changing taste and the lost volatile components as a result of the Maillard reaction cause a change in the flavor of dehydrated products. The dehydrated states of different raw materials are more or less similar to each other.

In a scientific study, the sensory properties of dehydrated and freeze-dried persimmons were compared. As a result of the sensory panel, as expected from the above explanations, the freeze-dried product was evaluated as superior to the dehydrated product in terms of color, appearance, crispness, chewiness, taste and general evaluation.

Freeze Dryer vs Dehydrator: Microbiological quality of final product

Health-beneficial microorganisms such as probiotics are sensitive to heat. Therefore, it is necessary to maintain the vitality of these microorganisms during the drying process to make probiotic foods such as kefir and yoghurt durable.

Applications that involve heat treatment, such as dehydration, cause these microorganisms to lose their vitality. For this reason, spray drying or freeze drying methods are preferred in industrial applications.

If you want to use the dried forms of these foods in home applications, freeze drying is the most important option. In two different studies conducted by me, I observed that freeze-drying had very little effect on microbial viability and that the loss of microorganisms was as low as one log.

Freeze Dryer vs Dehydrator: Product can and cannot be dried

Can dehydration and freeze drying be applied to all foods? What are the types of foods for which these methods do not work effectively? In this topic, I will examine the answers to these questions.

Freeze drying can be used successfully to dry foods in various forms such as liquid, puree, slices or whole foods. A wide variety of foods such as fruits, vegetables, cheeses, meats, candies, desserts, sauces, various beverages and aromatic herbs can be preserved by freeze drying.

Foods such as kefir, yoghurt and baker's yeast that contain live microorganisms are also suitable for freeze drying. Moreover, sensitive foods such as breast milk, broth and cooked meals are also suitable for processing by freeze drying.

However, it is found in foods that are not suitable for freeze drying. Products rich in sugar such as honey and syrups, fatty foods with low moisture content such as mayonnaise, butter and nut butters, and pure chocolate, soda and alcoholic beverages cannot be freeze dried.

Dehydration can be used in many products such as fruits, vegetables, meat products and aromatic plants.

However, foods containing microorganisms (even if they become dry, their microbial activity decreases significantly), high sugar foods (honey, syrups), dairy products (milk, cheese, butter), fatty products (avocado, olives, nut butters), fruit juices and Sodas are not suitable for dehydration.

It is not recommended to apply it at home, especially since dehydration of milk and dairy products may cause food poisoning.

Freeze Dryer vs Dehydrator: Investment cost

For many users, one of the main differences between dehydrator and freeze dryer is the investment required.

Dehydrators are simple systems consisting of air heater, fan and product trays. On the other hand, the freeze drying method requires advanced systems such as a vacuum pump, sealed drying section, tray heaters and condenser.

Therefore, there is a huge gap between the costs of dehydrators and freeze dryers. As a matter of fact, the price of home dehydrators starts from 40 dollars and can reach up to 300 dollars for advanced systems. On the other hand, the lowest capacity home freeze dryer has a starting price of over $2000.

However, freeze drying has the advantage of closing this gap in a short time, as food quality is better preserved, the final product has a much longer shelf life, and it can be applied to a wider range of products.

Freeze Dryer vs Dehydrator: Drying time and resource usage

There are also significant differences between the duration and resource use of freeze drying and dehydration processes.

Both drying methods require the raw material to undergo some pre-processing (such as sorting, cleaning, peeling, core removal, pureeing, slicing, chopping). After these processes, the dehydration products are placed in the dryer and the process is started. However, if the freezing process is carried out in a different freezer, the products must be placed in the dryer after the freezing process is completed. Therefore, the need for labor may increase.

An average dehydration process takes between 2 and 12 hours, depending on the astringency of the raw material. The shortest processing time in freeze drying is around 20 hours. Therefore, it requires longer processing time.

Freeze drying consumes more power and therefore energy due to the vacuum pump, heaters and condenser operating during this period.

In a scientific study, the use of freeze drying in the production of persimmon chips caused 5 times longer time and 7-9 times more energy usage compared to dehydration.

For more information about the electrical consumption of freeze dryers read this article

Therefore, it is very important to consider resource use when evaluating freeze drying vs dehydration.

Freeze Dryer vs Dehydrator: Shelf life

When it comes to food shelf life, both techniques have their advantages.

One of the most important advantages of freeze-dried foods is their impressive shelf life. These products can last for quite a long time, 25 to 30 years, when stored under appropriate conditions.

The low moisture content significantly limits not only microbial reactions but also physical and chemical deterioration. As a result, freeze-dried foods can remain fresh for decades. Freeze-dried foods are therefore an excellent choice for long-term storage, emergency preparedness and outdoor adventures.

Dehydrated foods usually have a considerable shelf life, with most products lasting between 1 and 5 years when stored properly. The shorter shelf life compared to freeze-dried foods is mainly due to the higher moisture content. Chemical reactions that continue during storage eventually render the food inedible. This is directly related to storage conditions.

Factors Influencing Shelf Life

Several factors influence the shelf life of both freeze-dried and dehydrated foods:

Moisture Content: As a rule of thumb, the lower the moisture content, the longer the shelf life. Freeze-dried foods have minimal moisture content, while dehydrated foods retain more moisture.

If the product absorbs moisture from the environment during storage, deterioration reactions accelerate and storage life is shortened.

Packaging: Proper packaging, including vacuum-sealing and the use of oxygen absorbers or desiccants, can significantly extend the shelf life of both types of products.

Storage Conditions: Temperature, humidity, and exposure to light play a critical role in chemical reactions. Cool, dry, and dark storage environments are ideal for maximizing shelf life.

Food Type: Some foods inherently have longer shelf lives than others due to their natural characteristics. As a general rule, foods that contain unsaturated fatty acids are less prone to the storage.

In summary, freeze-dried foods tend to have a significantly longer shelf life compared to dried foods. The absence of moisture and the preservation of flavor and nutrients make freeze-drying an attractive option for those looking for long-term food storage solutions.

Freeze Dryer vs Dehydrator: Noise

When it comes to food preservation appliances like freeze dryers and dehydrators, one often overlooked aspect is their noise level. Noise can be a crucial consideration, especially if you plan to use these machines regularly or have specific noise sensitivity concerns.

Freeze dryers are relatively quiet during the freezing and drying phases of the process. Most of the noise generated by freeze dryers comes from the vacuum pump, which is used to create a vacuum and remove moisture. The noise level of the vacuum pump can vary depending on the model and brand, but it typically ranges from 50 to 70 decibels (dB)

Discover How Loud is a Freeze Dryer

The noise level of a dehydrator primarily comes from the fan and heating element. Most dehydrators have fans that run at a moderate speed to circulate air evenly, resulting in noise levels ranging from 40 to 60 decibels (dB). The heating element in dehydrators may emit a subtle hum, but it is usually not very loud.

It must be noted that, several factors such as brand, model, size, capacity, maintenance and location can influence the noise levels of both freeze dryers and dehydrators.

In conclusion, when it comes to noise levels, dehydrators generally have an advantage over freeze dryers. Dehydrators are quieter due to their simpler technology and fewer moving parts.

Conclusion

In the world of food preservation, the choice between freeze dryer vs dehydrator has always been an important consideration. While both methods are effective for food preservation, they offer different qualities in the final product.

The dehydrator uses heated air to gradually remove moisture over time, making it suitable for fruits, vegetables and meats. While it is a faster process, high temperatures can lead to unwanted changes in the properties of the food.

In contrast, freeze drying uses sublimation, which involves freezing the food and then removing moisture under reduced pressure. This method has minimal impact on the properties of the food and allows for lower moisture content. However, it entails higher investment and operating costs.

Freeze dried foods have an impressive shelf life, often lasting 25 to 30 years, thanks to their minimal moisture content. On the other hand, dehydrated foods, when stored correctly, usually last between 1 and 5 years, mainly due to their higher moisture levels.

As a result, freeze drying offers longer shelf life and minimal impact on food properties, while Dehydration is faster and more budget friendly. Consider your priorities and intended use to make the best choice for your food preservation needs.

Are you beginner in freeze drying, read our beginner's guide